Rawwater’s headquarters, laboratories, research suites and workshops are located in a purpose-designed technology centre in Warrington, Cheshire, in the northwest of England.

Our microbial souring division uses our industry leading DynamicTVS© predictive modelling program and our extensive pressurised bioreactor laboratories to forecast, simulate and mitigate the effects of microbiological oilfield reservoir souring. The division’s expertise helps operators and service companies save many millions of dollars annually.

The division is also pioneering research into the potential impact of microbial life in Carbon Capture Storage (CCS) environments. Our applied technologies company, Rawwater Applied Technology Ltd, works with organisations from around the globe to provide them with novel leak recovery solutions and application techniques which use our M3 Molten Metal Manipulation capabilities.

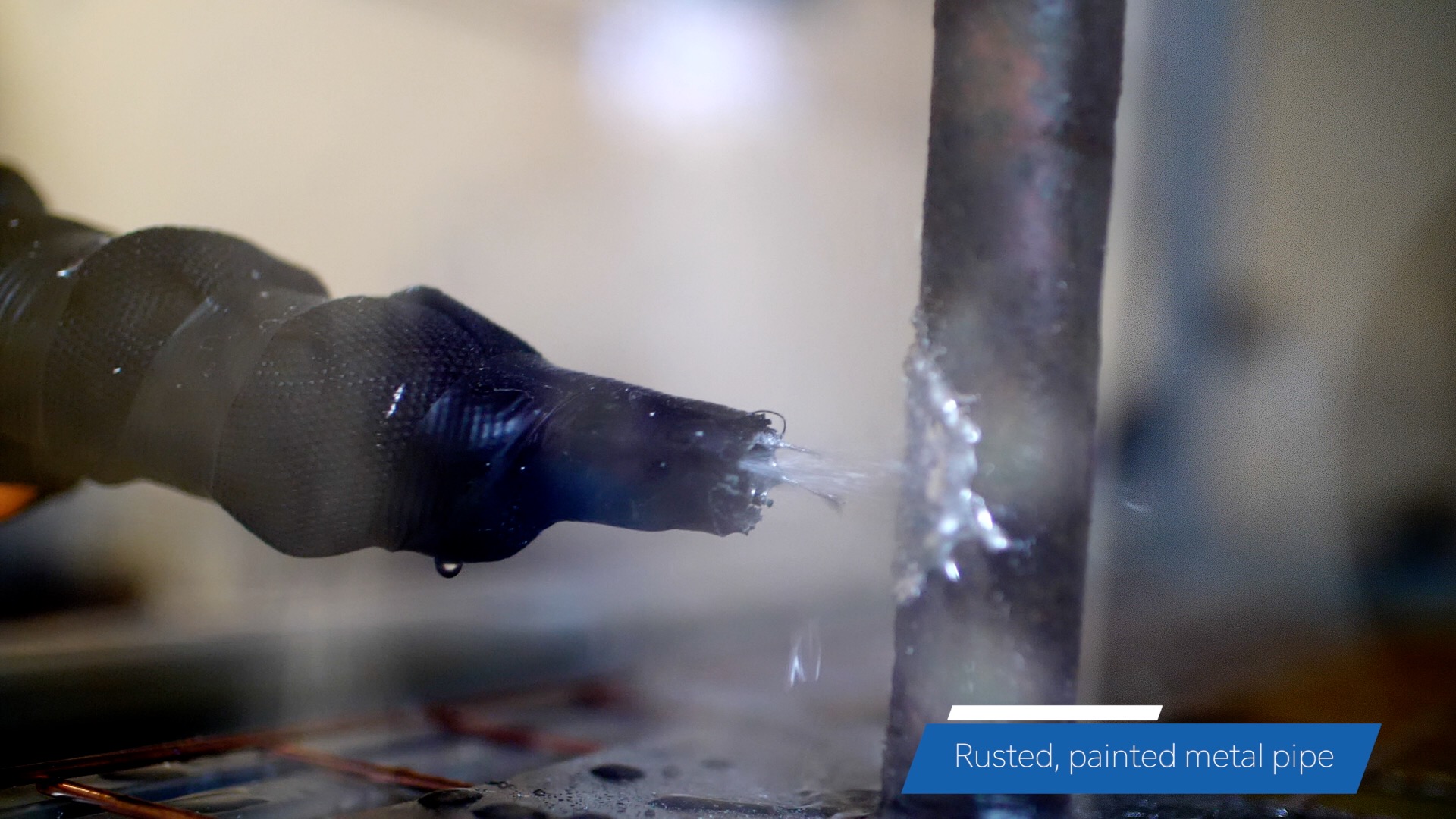

Our engineering division develops specialist alloy formulations and application techniques for use with our M3 Molten Metal Manipulation leak recovery technology and for our bismuth plug technologies for oilfield reservoir plugging and abandonment.

.jpg)