Optimising Sub-Optimal Nitrate Use for Oilfield Souring Control via High-Pressure Bioreactor Operation

CHALLENGE

Nitrate injection is a common mitigation strategy aimed at promoting nitrate-reducing microorganisms (NRM) to outcompete sulfate reducers and reduce H₂S production. Accurate nitrate dosing is critical but challenging due to complex reservoir conditions, including pressure, temperature and microbial interactions within the Thermal Viability Shell (TVS). Over- or under-dosing can lead to ineffective souring control or increased costs. This study evaluated the effectiveness of intentionally sub-optimal nitrate dosing under reservoir-simulated conditions. The secondary challenge was to determine the differences in chemistry efficacy and product volumes required under the two separate dosing scenarios.

-1756740329.jpg)

SOLUTION

High-Pressure Bioreactor Simulation

The research – a collaborative study with microbial Insights Inc. – utilised advanced high-pressure bioreactors to simulate oilfield reservoir conditions, enabling precise control of temperature, pressure and microbial populations. Suboptimal nitrate dosing strategies were tested to evaluate their effectiveness in mitigating reservoir souring caused by sulfate-reducing microorganisms (SRM). Realistic souring scenarios were replicated to observe microbial activity and chemical responses over time.

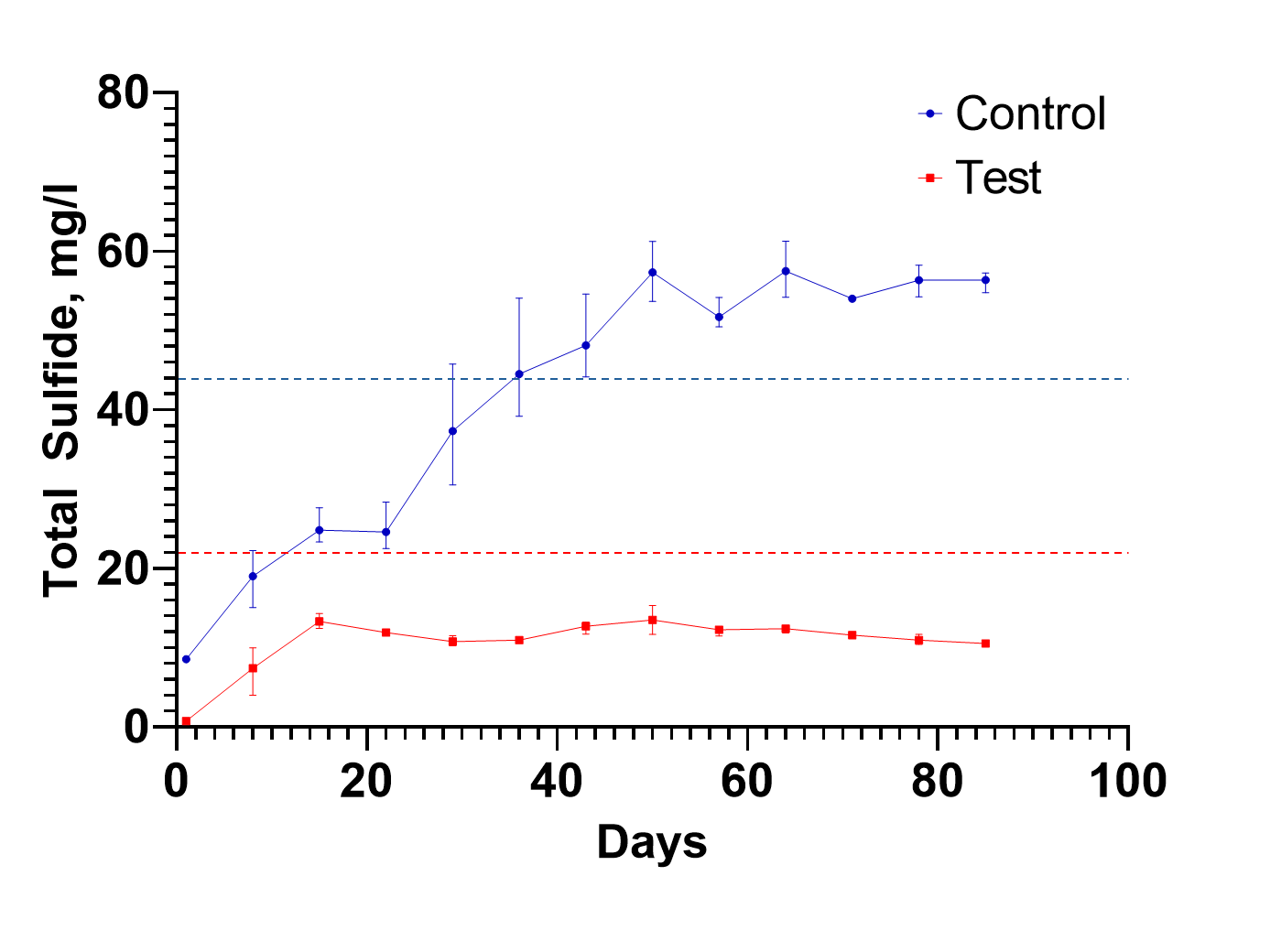

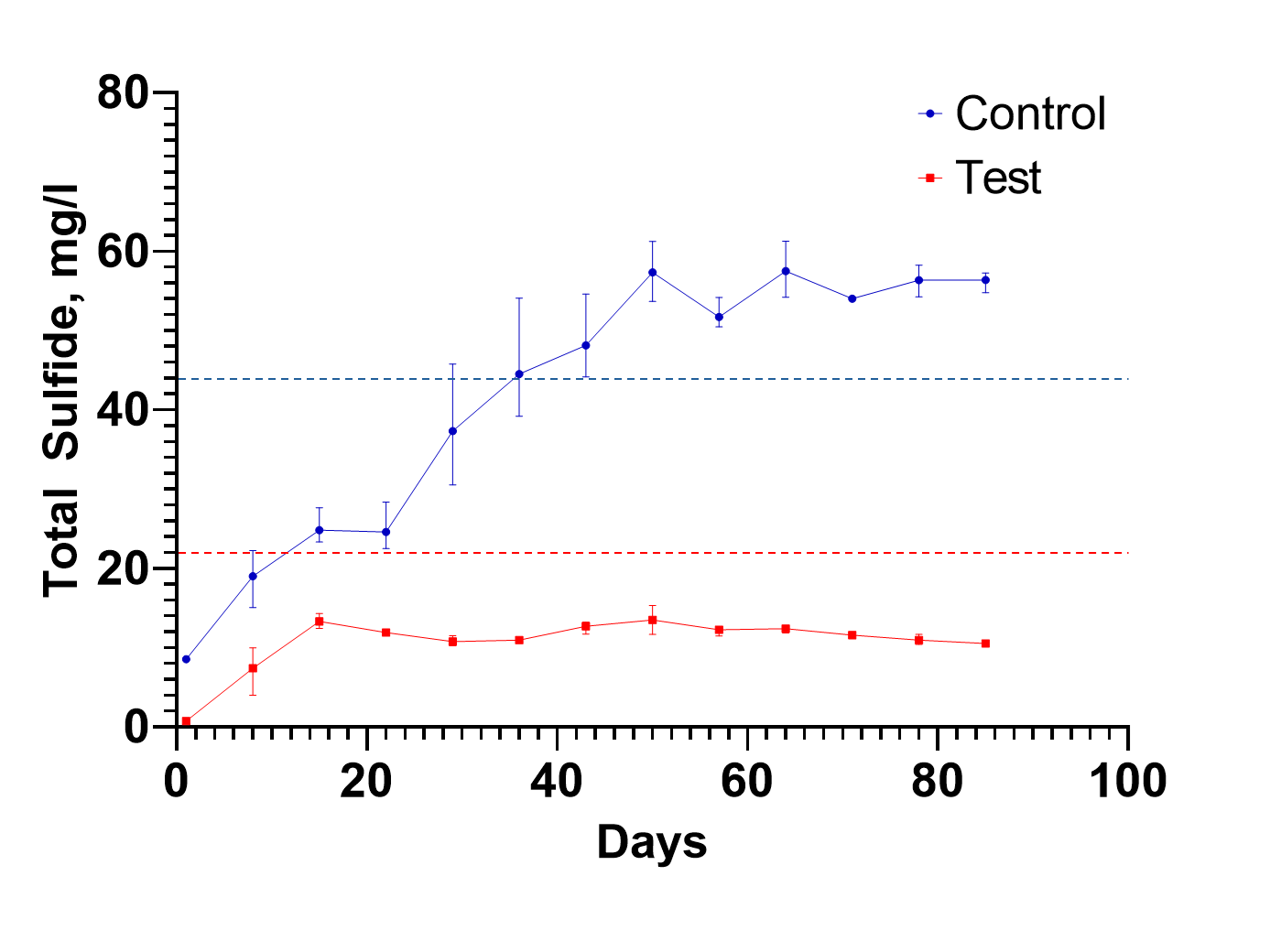

The study found that even sub-optimal nitrate levels could delay onset and reduce the overall souring by stimulating NRM, which compete with sulfate reducers. Though incomplete nitrate dosing risked partial souring control, the final sulfide concentrations were significantly lower than originally anticipated. Results highlighted the importance of balancing nitrate concentration to maximise mitigation while minimising chemical usage and operational costs.

Overall, the research demonstrated that tailored nitrate application - guided by reservoir-specific microbial and chemical dynamics - can significantly enhance souring management strategies in oilfield operations, achieving reductions of up to 80% even with a 50% nitrate under-dose.

BENEFITS

Efficient, cost-effective oilfield souring control via optimized nitrate treatment

Cost-effective souring control achieved through reduced nitrate dosing optimisation

Insights into complex microbial interactions improve souring management accuracy

Experimental data enhances predictive models for effective nitrate treatments

.jpg)

Case Study

Case Study

-1756740329.jpg)